Product

Contact Us

+86 137 8526 0627(Cell/ Whatsapp)

No. 13, Canda Wire Mesh Entrepreneurship Counseling Base, Anping County, Hengshui City, Hebei Province

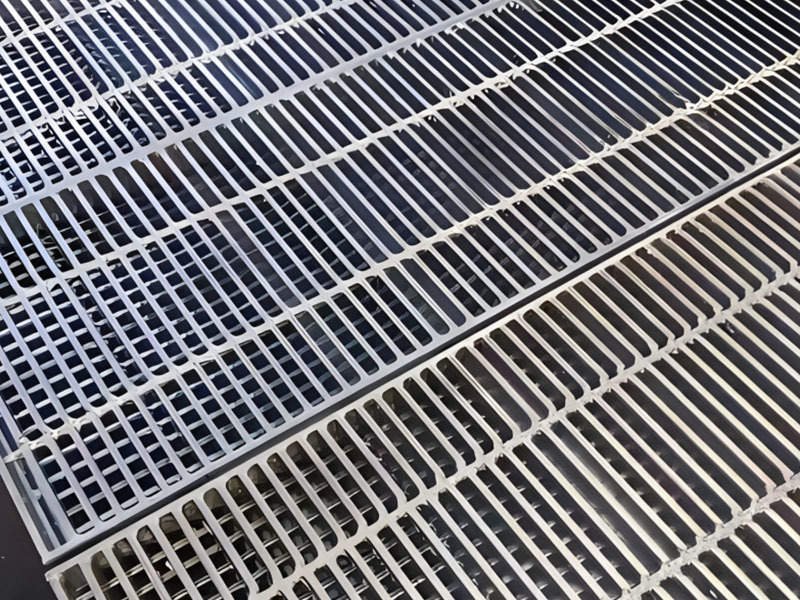

Heavy Duty Steel Grating

Product Details

Heavy Duty Steel Grating, also known as heavy-duty steel grating, is specifically designed for applications that require exceptional load-bearing capacity. It is crafted with load-bearing flat steel bars of a width of 65mm or more and a thickness of 6mm or more. Crossbars are typically made from flat steel or steel bars with a diameter of 10mm/12mm. The spacing between flat steel bars is generally 40mm, while the spacing between horizontal bars is usually 50mm, with 100mm as an optional choice. The load-bearing requirement for this type of steel grating is more than 10 tons. Heavy-duty pressure-welded steel grating and heavy-duty pressure-locked steel grating are two common classifications within this category.

Heavy Duty Steel Grating is extensively used in locations with special load-bearing demands, including airports, highways, industrial platforms, port terminals, and other site platforms that require superior strength.

Considering the specific requirements of heavy-duty steel grating, we advise customers to inform us about the load requirements and support conditions so that we can select the most economical and appropriate specifications for their needs. The standard flat steel spacing for heavy-duty steel grating is generally 40mm, and customers can choose between 50mm and 100mm for the crossbar spacing. Commonly used models include G808/40/100, G1008/40/100, and G1208/40/100, but customization is also available according to customer requirements.

keyword:

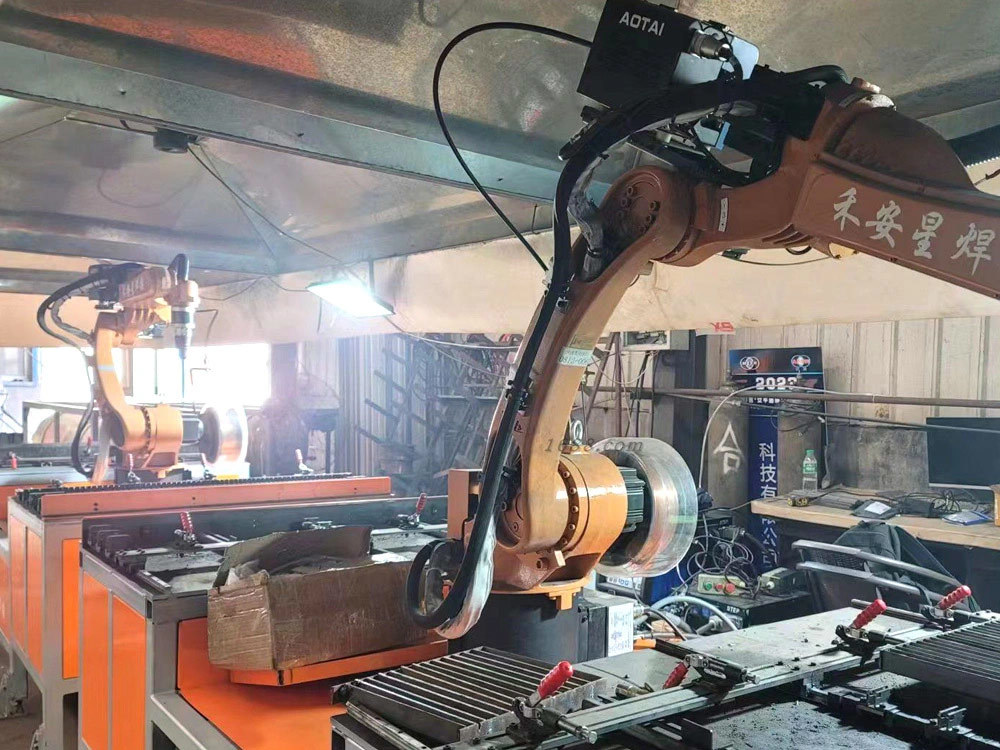

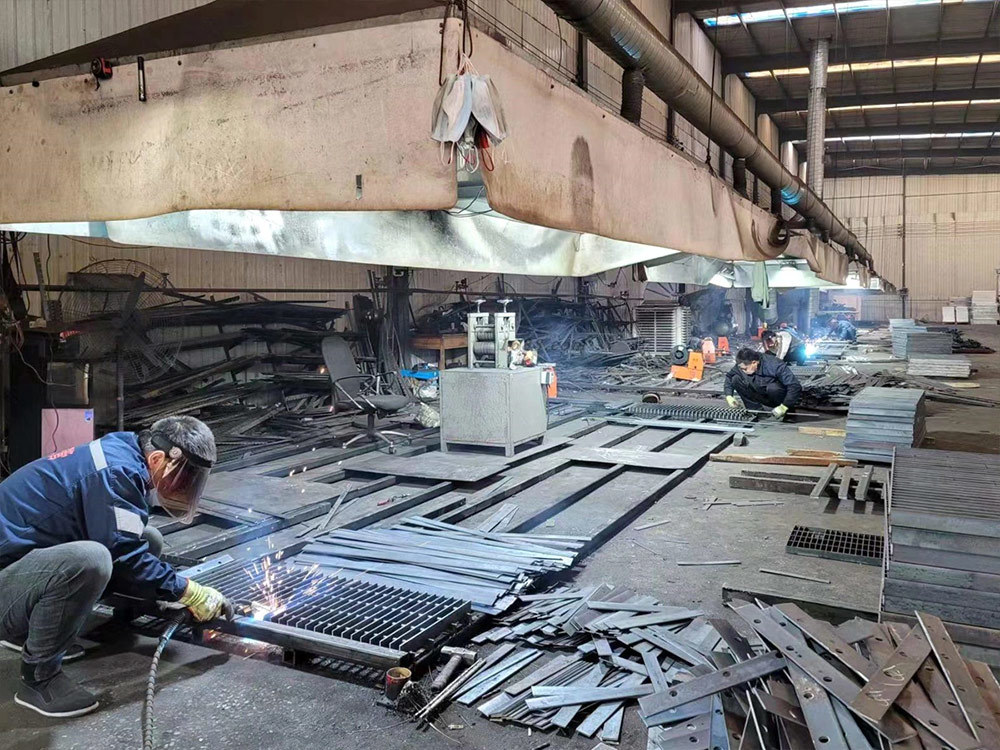

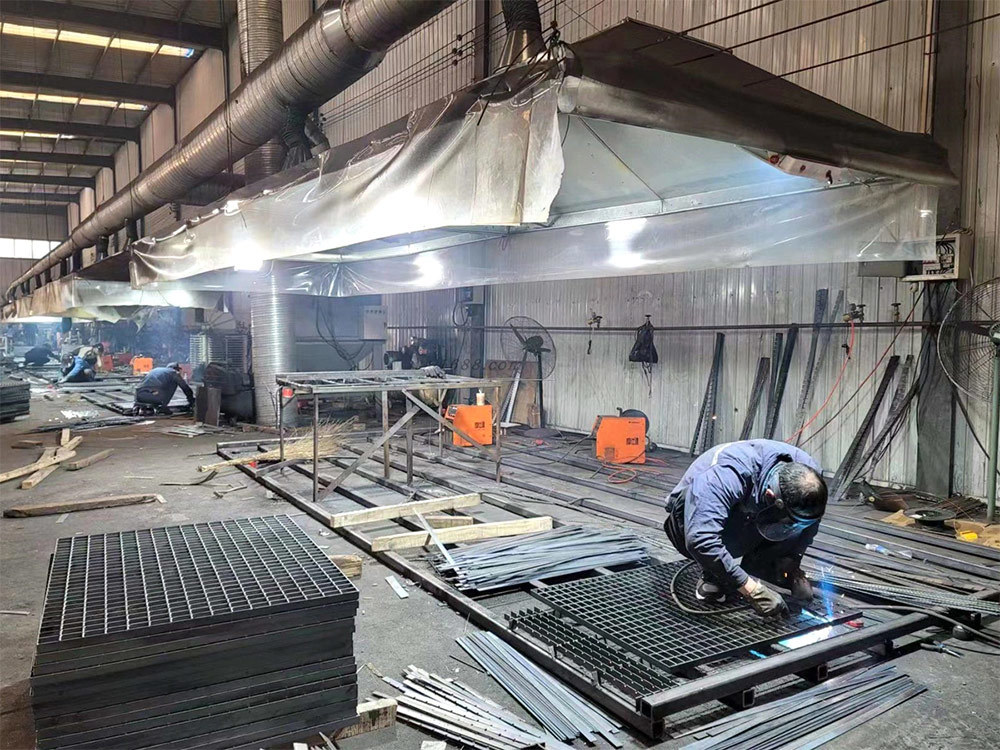

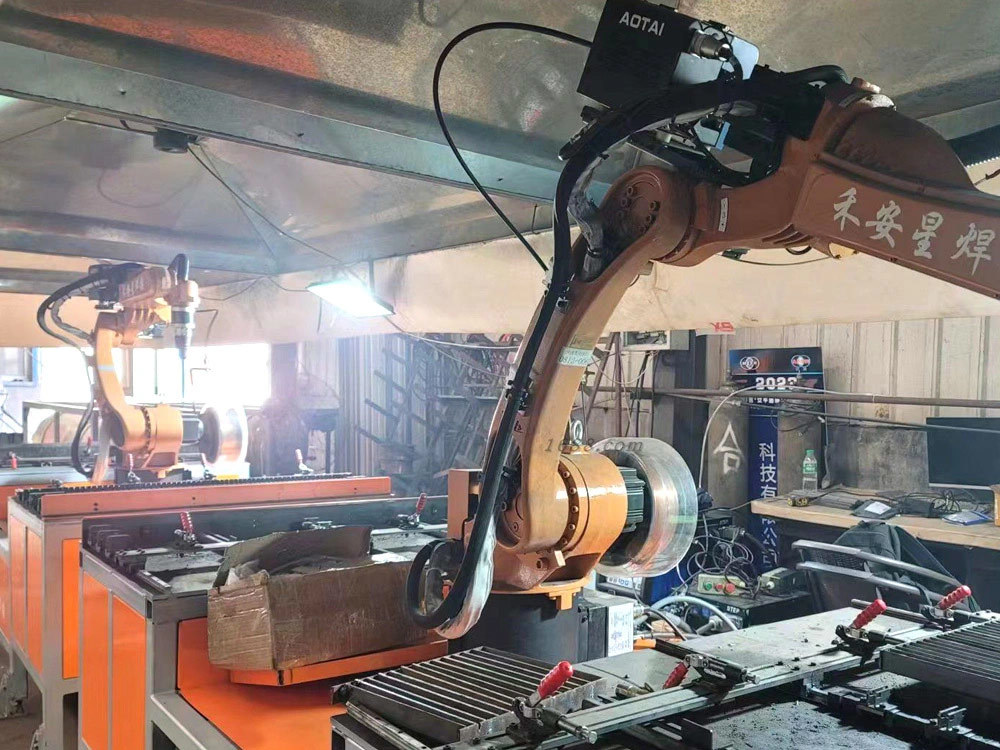

Production Strength

vast in scale,equipped with advanced equipment,strong technical capabilities,excellent quality, efficient production capacity, strong environmental awareness, high management level, and solid comprehensive strength.

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

FAQ

What does length and width exactly refer to?

In a grating, the length means the length of bearing bar while width means the length of cross bar. When placing your order, please provide clear dimensions to avoid any potential errors.

How do you calculate the area of each grating?

a. For regular shape grating, the area equals to length multiplied by width of grating, including the area of holes and notches.

b. For irregular shape grating, the area is that of the steel grating before cutting, instead of the area of irregular shape grating.

Why should we offer the structure drawing and detailed parameters of the work site?

This is to better serve your needs. Based on your structure drawing and parameters, we design and offer a grating perfectly suits your work site and ensure no extra cutting while usage. It greatly simplifies the installation work and saves your time. What’s more, according to the information you offer, we can recommend you the best suitable grating, which will save you time and money. We can also avoid the confusion between length and width mentioned in Q7 and prevent unnecessary economic loss for you.

How do you control the quality of the products leaving the factory?

The QA team will do testing and record each step, from raw material purchase to finished product delivery, to ensure that each step is traceable and materials entering the next program are 100% qualified.