Product

Contact Us

+86 137 8526 0627(Cell/ Whatsapp)

No. 13, Canda Wire Mesh Entrepreneurship Counseling Base, Anping County, Hengshui City, Hebei Province

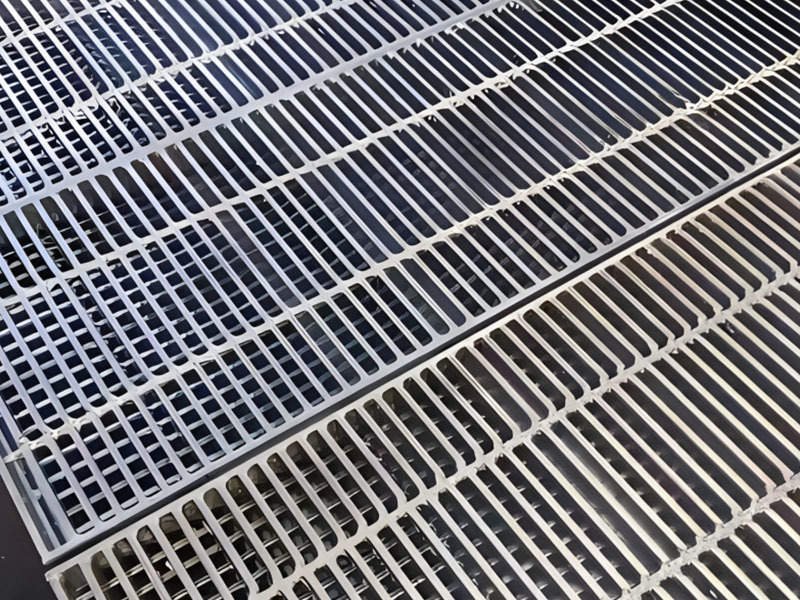

Serrated steel grating g325/30/100

Product Details

Tooth-shaped steel grating, also known as serrated steel grating or serrated slip-resistant steel grating, is made from tooth-shaped flat steel, providing strong slip resistance. It is particularly suitable for wet and slippery environments, such as offshore oil production platforms. Please consider the cost when purchasing, as the price of serrated steel grating is higher than that of plain types. The surface of the tooth-shaped steel grating is treated with hot-dip galvanization, resulting in excellent anti-rust properties, making it maintenance-free and replacement-free for up to 30 years. In specifications, the letter "S" represents the tooth-shaped steel grating, and the full interpretation is hot-dip galvanized tooth-shaped steel grating.

Serrated steel grating G325/30/100 is a type of industrial flooring material commonly used in applications where slip resistance is essential. The "G325/30/100" designation refers to the specific dimensions and characteristics of the grating, including the bearing bar pitch, cross bar pitch, and load rating.

Serrated steel grating G325/30/100 is a durable and versatile grating solution designed for various industrial applications. With its serrated surface, this type of steel grating provides enhanced slip resistance, making it ideal for areas where safety is a priority, such as walkways, platforms, and stair treads. The G325/30/100 designation indicates the specific dimensions of the grating, including the bearing bar pitch (30mm), cross bar pitch (100mm), and steel grade (G325), ensuring a sturdy and reliable construction suitable for heavy-duty use.

The serrated design of the serrated steel grating g325/30/100 offers superior traction and grip, reducing the risk of slips and falls in high-traffic areas or environments exposed to moisture or debris. This feature makes it a preferred choice for industrial settings, construction sites, and outdoor facilities where safety is paramount. The G325 steel grade further enhances the durability and load-bearing capacity of the grating, ensuring long-lasting performance and structural integrity in challenging conditions.

In addition to its safety benefits, the serrated steel grating G325/30/100 is easy to install and maintain, providing a cost-effective and efficient solution for businesses looking to enhance workplace safety and functionality. Its corrosion-resistant properties and robust construction make it suitable for a wide range of applications, offering a reliable platform for workers and equipment while meeting stringent safety standards. The G325/30/100 serrated steel grating combines durability, safety, and practicality, making it an essential component in various industrial and commercial settings.

The serrated surface of the steel grating provides enhanced traction and grip, making it ideal for areas prone to slippery conditions. With a bearing bar pitch of 30mm, a cross bar pitch of 100mm, and a high load rating, this type of grating is suitable for heavy-duty industrial environments, walkways, platforms, and stair treads where safety and durability are paramount.

Advantages of Serrated Steel Grating (Tooth-shaped Steel Grating):

Excellent Drainage: The large mesh design ensures optimal drainage with a leakage area of 83.3%, more than twice that of cast iron.

Attractive Appearance: Featuring simple lines and a modern silver appearance, the product adds an aesthetic touch.

Cost-efficient: In large-span and heavy-loaded scenarios, the price is lower than that of cast iron. Additionally, it saves costs associated with replacing cast iron covers due to theft or damage.

Superior Slip Resistance: Serrated steel grating provides the best slip resistance among steel gratings, significantly increasing the friction of the surface to prevent accidents caused by slipping and ensuring workplace safety.

Specifications of Serrated Steel Grating (Tooth-shaped Steel Grating):

Height and Thickness: The height of the flat steel is usually available in options such as 20mm, 25mm, 30mm, 32mm, 35mm, 40mm, 45mm, and 50mm. The thickness of flat steel varies, with options such as 3mm, 4mm, 5mm, 6mm, and 8mm.

Surface Treatment: Serrated steel grating can undergo various surface treatments, including hot-dip galvanization, cold galvanization, electrowelding, painting, dipping in anti-rust oil, and plastic dipping.

Spacing between Loaded Flat Steel Gratings: The center distance between two adjacent loaded flat steels is commonly 30mm, 40mm, and sometimes 60mm.

Space between Crossbars: The center distance between two adjacent crossbars is typically 50mm and 100mm. Special specifications can be produced based on customer requirements.

keyword:

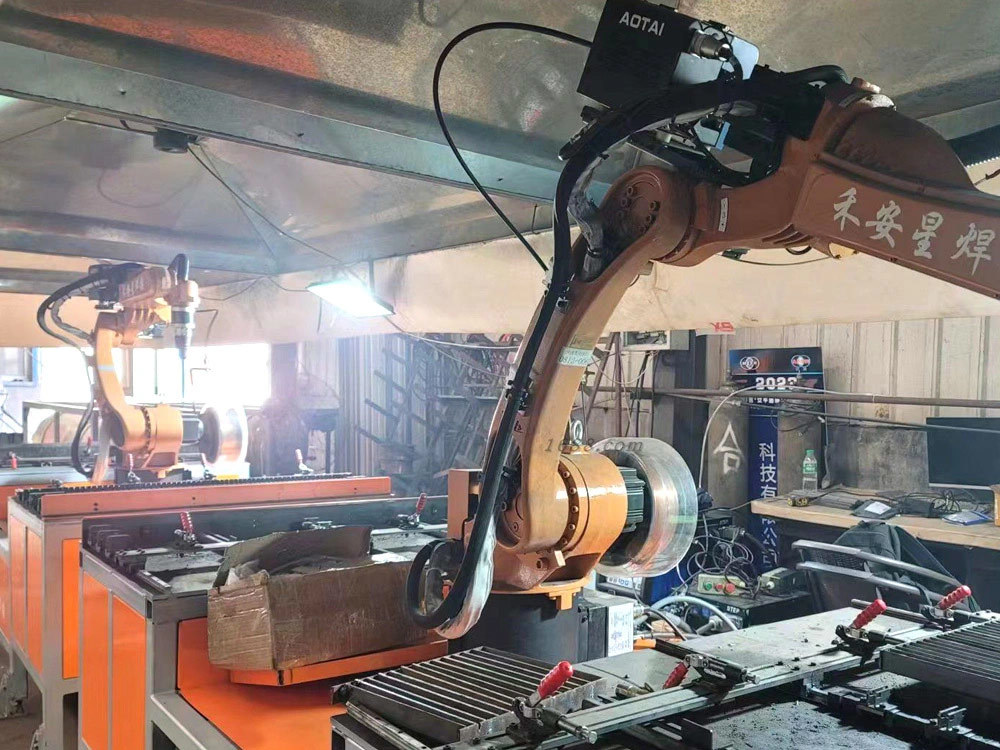

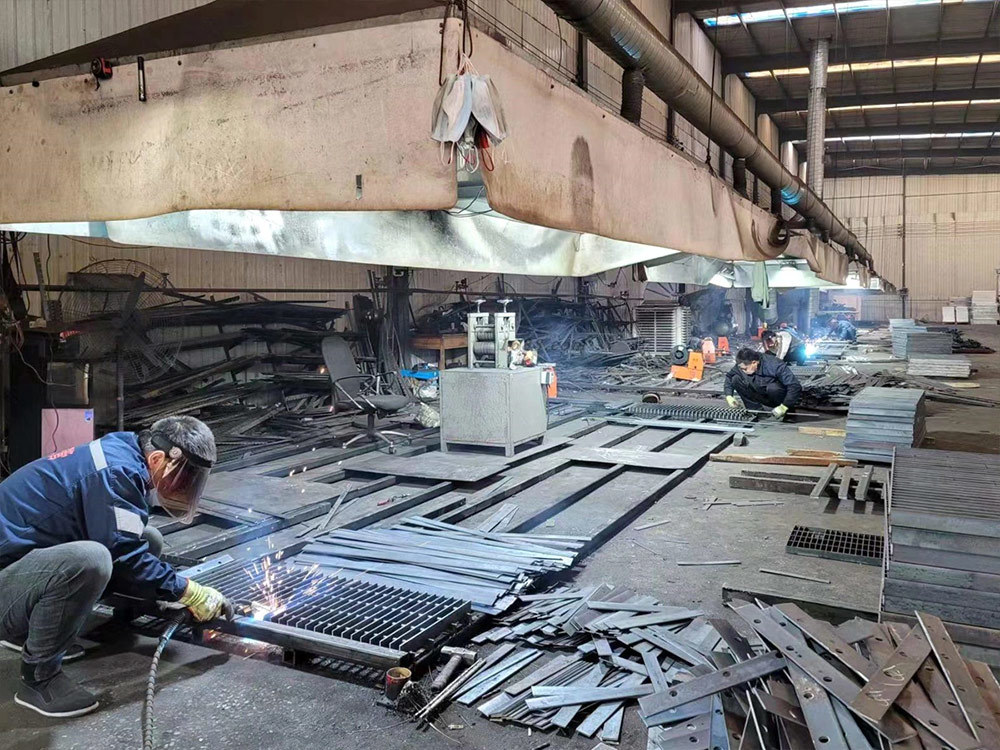

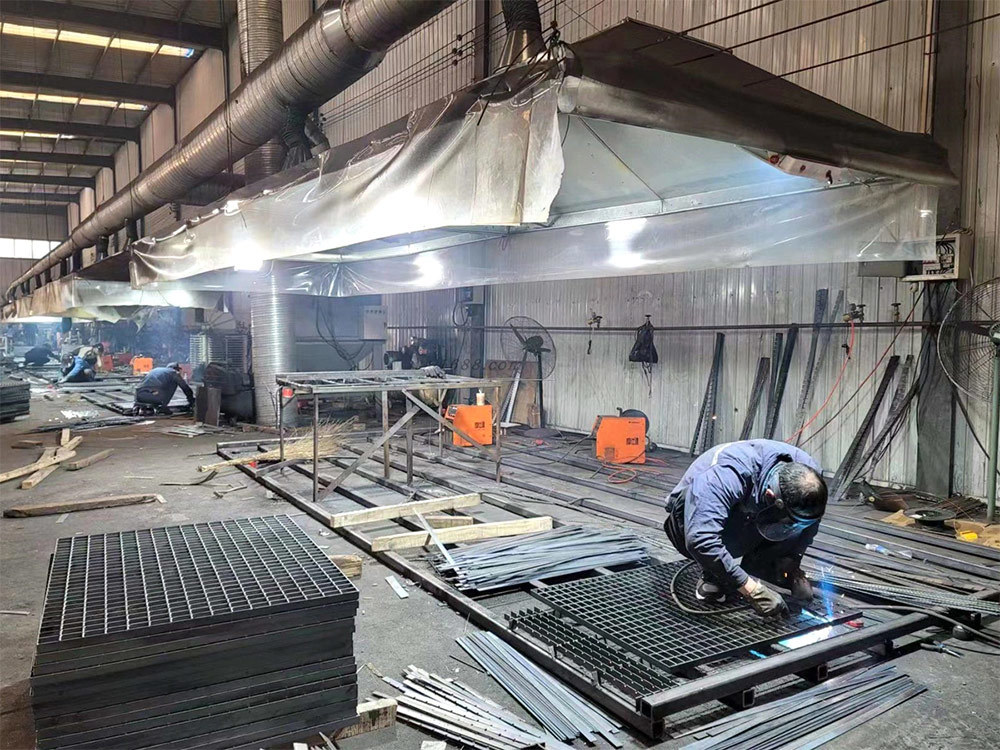

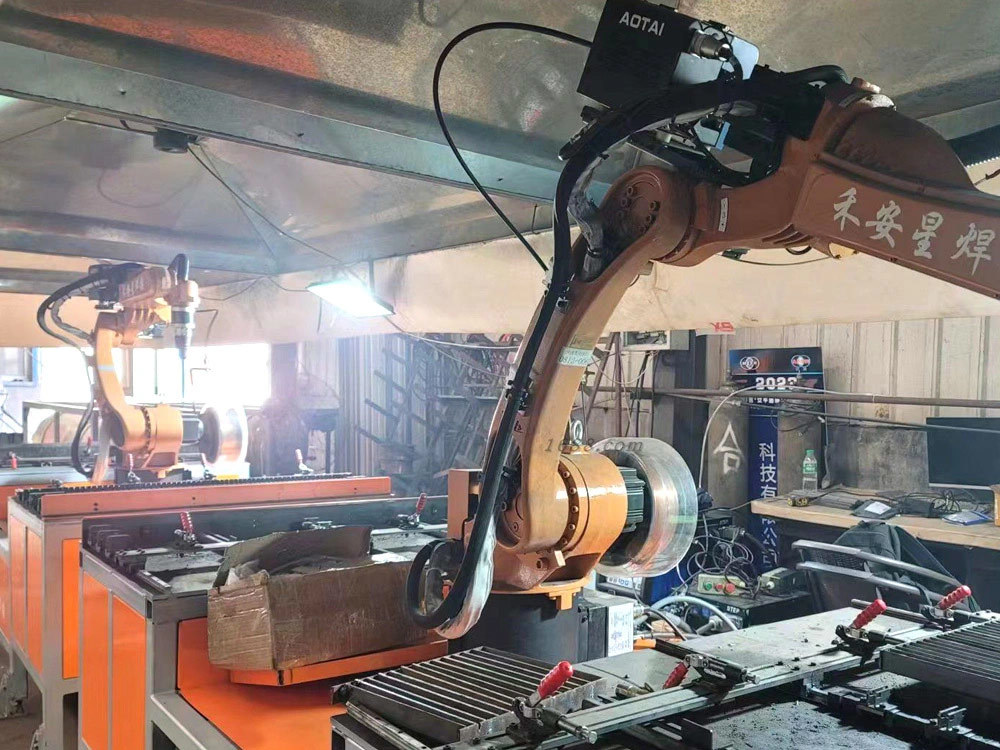

Production Strength

vast in scale,equipped with advanced equipment,strong technical capabilities,excellent quality, efficient production capacity, strong environmental awareness, high management level, and solid comprehensive strength.

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

FAQ

What standards do your steel gratings meet?

We are able to manufacture steel gratings with standards in different countries, such as YB/T4001.1-2007, ANSI/NAAMM (MBG531), BS4592 and JJS Standards.

How do you control the quality of your gratings?

To ensure high quality, we use advanced production lines and inspection machines. We strictly follow manufacturing requirements and have numerous certifications.

What specifications and types do you supply?

We can produce steel gratings of any specifications or types. Just let us know your dimensions, materials, color, and other requirements, and we'll customize them for you. We ensure they meet your needs.

What’s your raw material?

Our raw materials are Q235 carbon steel and stainless steel, and we can also use materials specified by the customer.

What’s the difference between plain grating and serrated grating?

The serrated gratings have better anti-slip performance but come at a higher price compared to regular gratings. They are widely used in petrochemical engineering.

What’s the surface treatment?

The surface treatment includes hot-dip galvanization, painting, electrostatic coating or non-treatment.