Stainless steel grating refers to steel gratings made of stainless steel material. Its production process is largely similar to that of ordinary steel gratings, except that it does not require additional anti-corrosion treatments such as painting or hot-dip galvanizing. Instead, it undergoes surface polishing to remove welding residues or scars left during the welding process. Stainless steel grating finds extensive applications in various factories and engineering projects both domestically and internationally.

Deformed steel grating is a distinctive type of irregular steel grating, featuring special shapes such as fan-shaped, circular, corner-cut, and trapezoidal, achieved through cutting, opening, welding, and wrapping processes to meet specific customer requirements. Usually made from carbon steel, it undergoes hot-dip galvanization to prevent oxidation and can also be manufactured using stainless steel. Deformed steel grating offers excellent ventilation, lighting, heat dissipation, slip resistance, and explosion-proof properties.

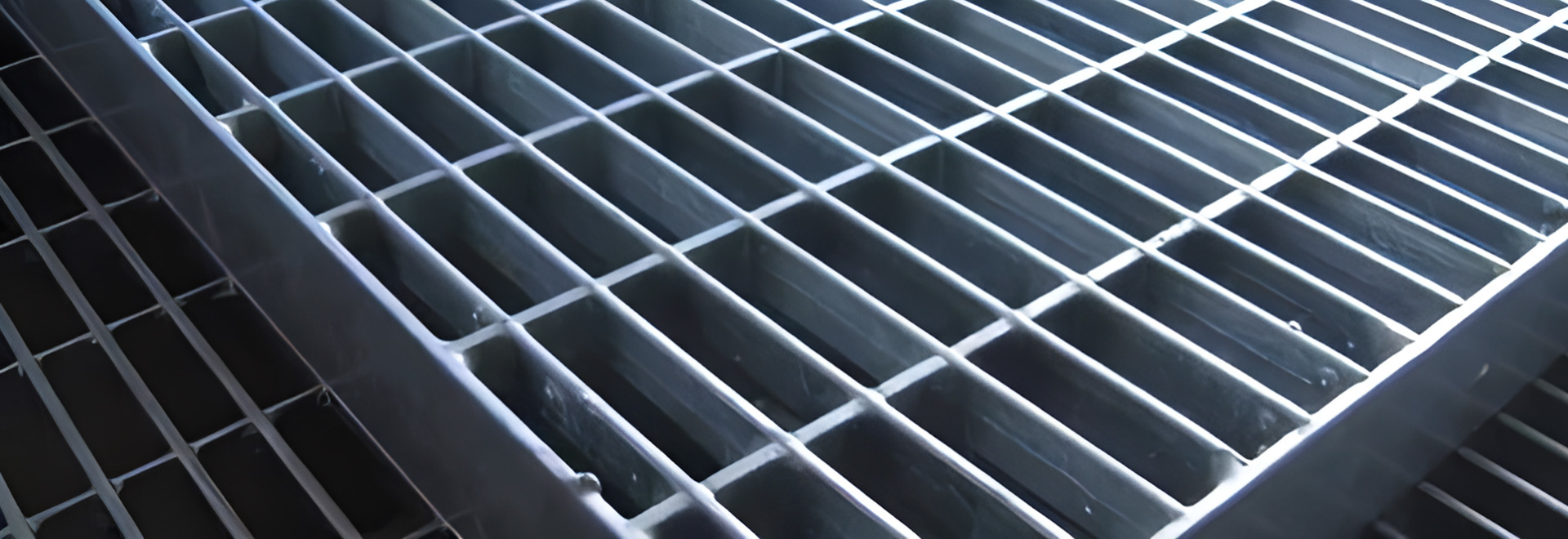

Dense Steel Grating, also known as heavy-duty steel grating or heavy-duty welded steel grating, refers to pressure-welded steel gratings with flat bars spaced less than 25mm apart. These gratings are manufactured using thicker and wider flat bars, specifically designed for applications that require bearing heavy loads.

Heavy Duty Steel Grating, also known as heavy-duty steel grating, is specifically designed for applications that require exceptional load-bearing capacity. It is crafted with load-bearing flat steel bars of a width of 65mm or more and a thickness of 6mm or more. Crossbars are typically made from flat steel or steel bars with a diameter of 10mm/12mm. The spacing between flat steel bars is generally 40mm, while the spacing between horizontal bars is usually 50mm, with 100mm as an optional choice. The load-bearing requirement for this type of steel grating is more than 10 tons. Heavy-duty pressure-welded steel grating and heavy-duty pressure-locked steel grating are two common classifications within this category.

Tooth-shaped steel grating, also known as serrated steel grating or serrated slip-resistant steel grating, is made from tooth-shaped flat steel, providing strong slip resistance. It is particularly suitable for wet and slippery environments, such as offshore oil production platforms. Please consider the cost when purchasing, as the price of serrated steel grating is higher than that of plain types. The surface of the tooth-shaped steel grating is treated with hot-dip galvanization, resulting in excellent anti-rust properties, making it maintenance-free and replacement-free for up to 30 years. In specifications, the letter "S" represents the tooth-shaped steel grating, and the full interpretation is hot-dip galvanized tooth-shaped steel grating. Serrated steel grating G325/30/100 is a type of industrial flooring material commonly used in applications where slip resistance is essential. The "G325/30/100" designation refers to the specific dimensions and characteristics of the grating, including the bearing bar pitch, cross bar pitch, and load rating.

For those seeking the best in quality and durability, look no further than our newest flat galvanized steel grate cover drainage system. Crafted from high-quality galvanized steel, this drainage grate cover offers advanced features such as superior rust resistance and long-lasting performance. With its fancy and classy design, it adds a touch of sophistication to any outdoor setting while effectively channeling water away to prevent flooding and erosion.