PRODUCTS CENTER

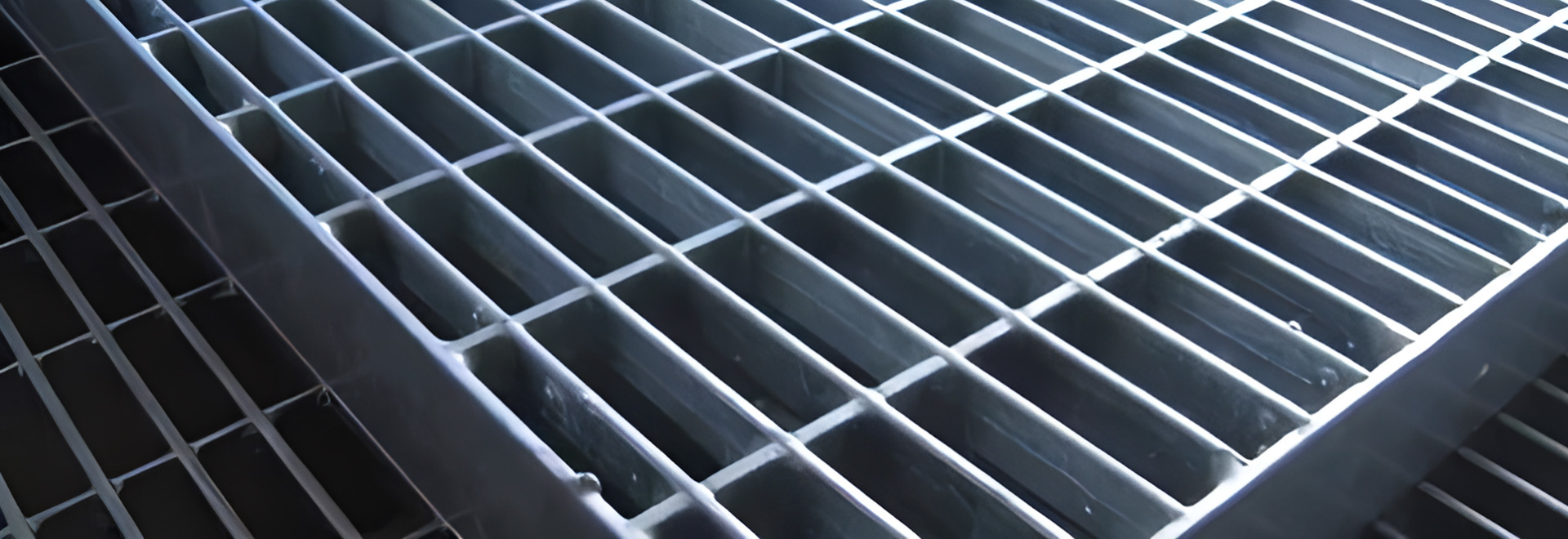

For those searching for the best serrated steel bar grating in Malaysia, look no further than our top-quality Chinese-made product. Our serrated steel bar grating stands out for its exceptional durability and advanced design, making it a reliable choice for industrial and commercial applications. With a fancy and classy appearance, this grating not only offers superior strength and stability but also adds a touch of sophistication to any space.

Steel grating serrated flat bar drain cover is a type of drainage system commonly used in industrial and commercial applications to effectively manage water runoff. The combination of serrated flat bar grating and drain cover design helps to improve drainage efficiency while providing a sturdy and safe walking surface.

Trench Drain Cover, also known as gutter cover, trench cover, or car wash room ditch cover, is manufactured by welding steel grating and undergoing hot-dip galvanization treatment. This process results in a durable, anti-corrosive, and rust-resistant product with significant advantages over traditional cast iron trench covers. The steel grating used in ditch covers is connected by hinges, allowing for easy opening and providing an anti-theft function.

Trench covers steel checker plate with grating are commonly used in industrial and municipal settings to provide safe and secure coverings for trenches and utility access points. This type of cover combines the durability of steel checker plate with the structural support of grating to create a robust and reliable solution for covering open trenches.

Stair Tread Steel Grating, also known as steel grating treads, are made from cross-arranged flat steel bars and crossbars, welded into checkered plates. These steel grating treads are often surface-treated with hot-dip galvanization or electrogalvanization. They are an essential component for steel structure platforms and play a vital role in providing safe access up and down these platforms.

Press Locked Steel Grating and general steel grating indeed have several differences in their manufacturing process, load-bearing capacity, and applications.