Compound Steel Grating is an innovative steel grating product that combines the load-bearing capacity of steel grating with a sealed checkered steel plate or steel mesh on the surface. It can be composed of various types of steel grating and industrial steel plates with different thicknesses. The most commonly used configuration is G323/40/100 steel grating as the base plate and 3mm checkered steel plate as the top plate, but other thicknesses like 4mm, 5mm, or 6mm can also be used.

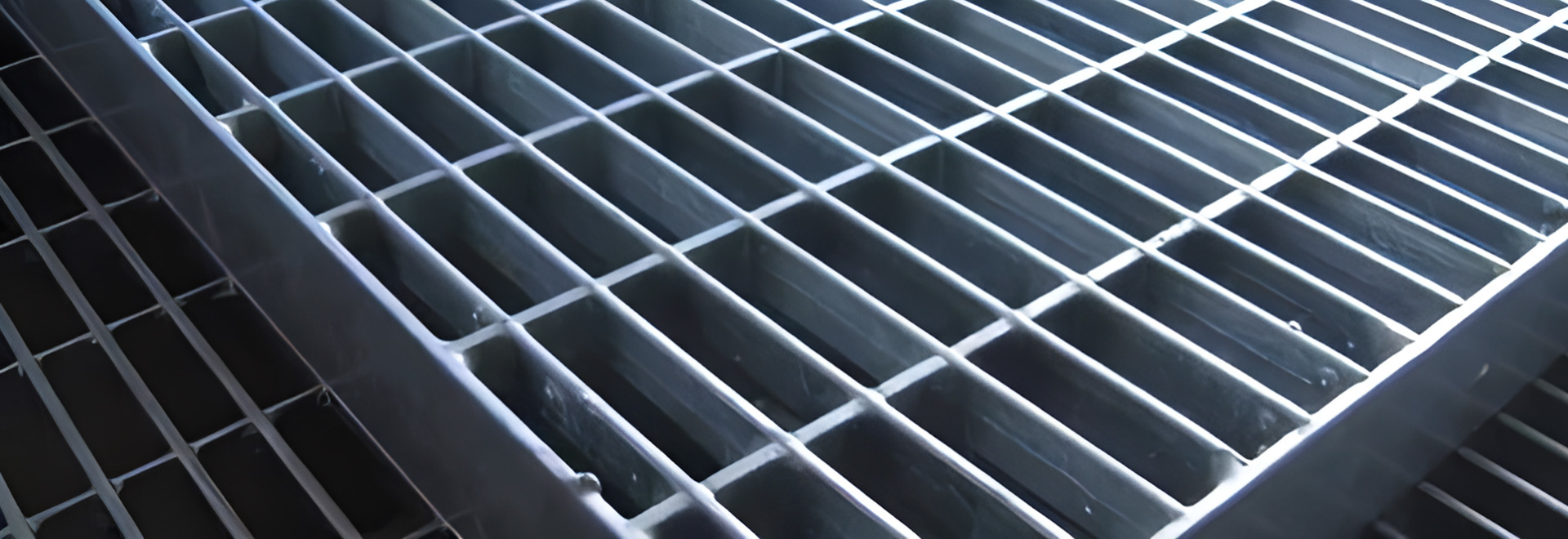

Galvanized steel grating is a versatile steel product formed by arranging loaded flat steel and cross bars at specific intervals in warp and weft. These components are welded together using a high-voltage resistance welding machine, creating the original plate. Further processing, including cutting, incision, hole opening, and edge wrapping, is done to meet customer requirements and produce the finished product.

Offshore platform reinforced floor grating is commonly used in various areas of offshore platforms, including walkways, equipment access areas, helicopter landing pads, and areas with high foot traffic. Its robust construction and anti-slip properties make it an essential component for ensuring the structural integrity and safety of offshore facilities.